ABOUT THE COMPANY

ABOUT US AND OUR PARTNERS

The strategy of the company "Quality INDUSTRIAL Lubricants, LLC" is the successful development of the domestic production of a wide range of lubricants in order to maximize customer satisfaction. The high quality, reliability of supplies and reasonable prices are the basis of "Quality INDUSTRIAL Lubricants, LLC".

The base of the assortment of our products is the most used in industry, agriculture and private use multi-purpose lubricants - motor, transmission, industrial, energy and other oils, greases and coolants, which are offered to customers in a variety of containers. Qualified personnel, modern technologies and materials, in-house test laboratory guarantee the high quality of products, efficiency and reliability of its application.

The product offering includes:

- Seasonal and all-season universal oils for gasoline engines

- Seasonal and all-season universal oils for diesel engines

- Automotive transmission oils

- Industrial oils

- Hydraulic oils

- Energy oils

- Gear oils

- Greases

- Coolants.

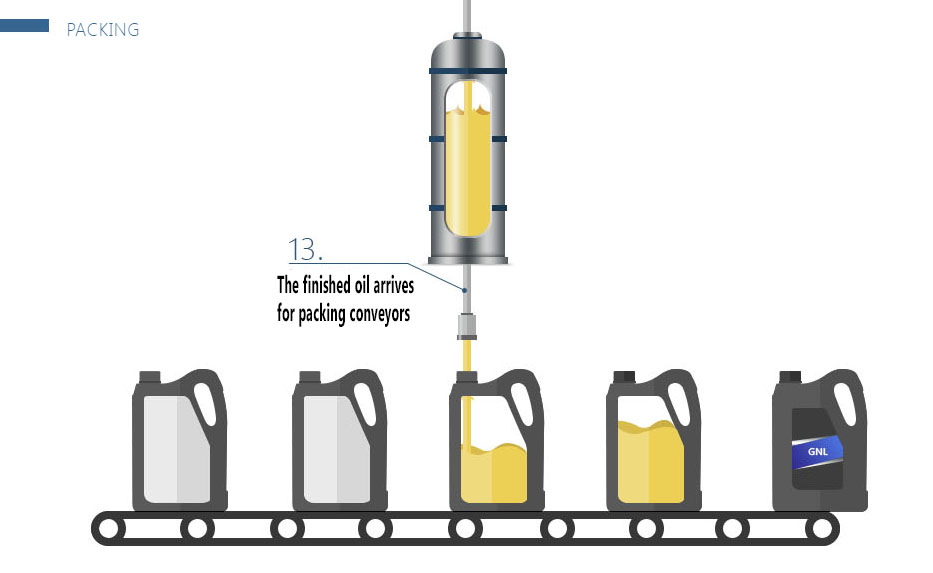

Our manufacture is organized on the principle of the full technological cycle, which includes: purchase of raw materials, manufacturing process, packing, packaging, check of the each batch to meet the latest standards.

The product offering is constantly expanding and changing, in accordance with the market needs.

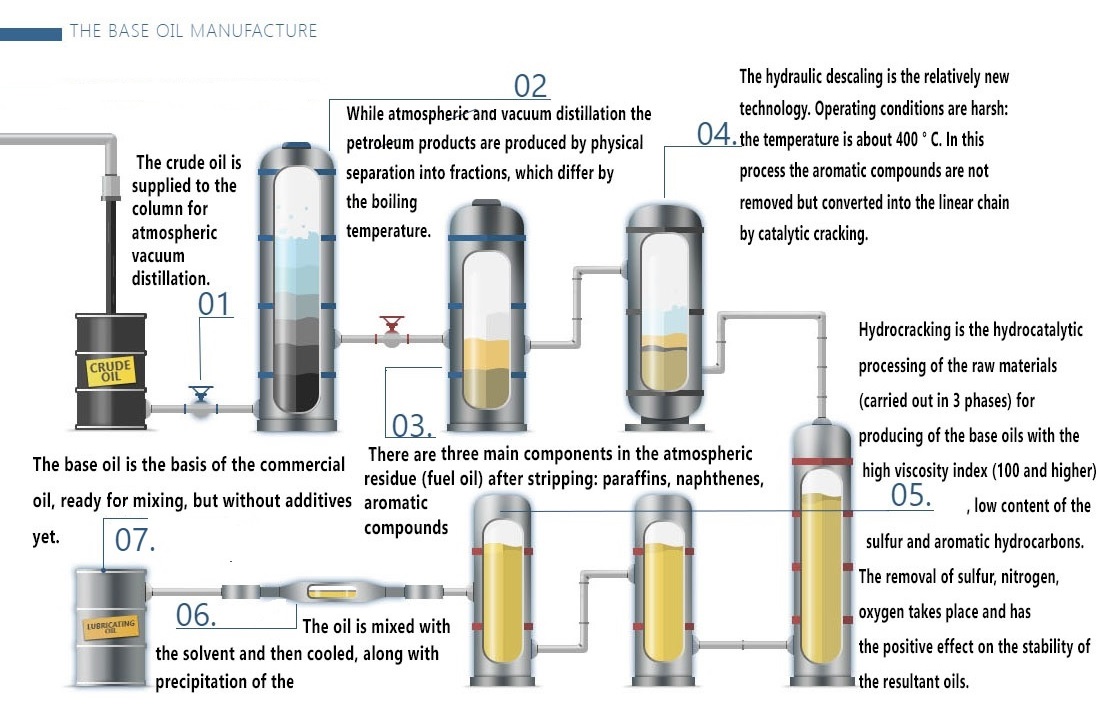

The crude oil is supplied to

the column for atmospheric -

vacuum distillation.

After the second distillation, the purified

product has the high content

of linear paraffins with the very

very high solidifying temperature.

The oil is mixed with the solvent

and then cooled, along with precipitation

of the paraffin crystals.

THE HIGH-QUALITY

BASE OILS

WITH ADDITIVES

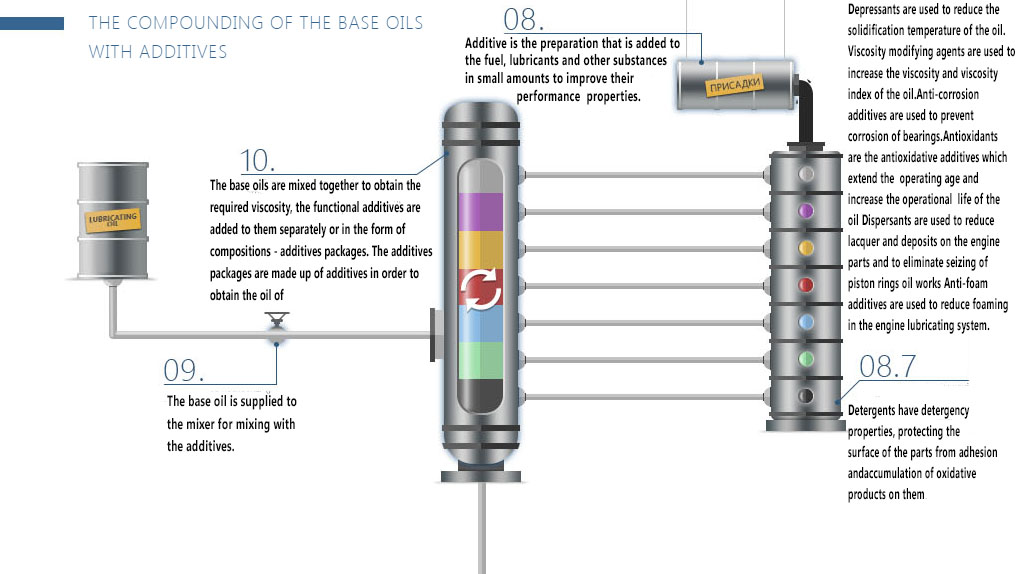

The base oil is supplied to

the mixer for mixing with

the additives.

-

08.1

08.1Depressants are used to reduce

the solidification temperature

of the oil. -

08.2

08.2Viscosity modifying agents are used to

to increase the viscosity and

viscosity index of the oil. -

08.3

08.3Anti-corrosion additives are

used to prevent corrosion of bearings. -

08.4

08.4Antioxidants are the antioxidative

additives which extend the operating age

and increase the operational life of

the oil -

08.5

08.5Dispersants are used to

reduce lacquer and deposits on

on the engine parts and to eliminate

seizing of piston rings oil works. -

08.6

08.6Anti-foam additives

are used to reduce foaming

in the engine lubricating system. -

08.7

08.7Detergents have detergency properties,

, protecting the surface of

the parts from adhesion and

accumulation of oxidative products on them.

THE BEST

ADDITIVES

FOR OIL

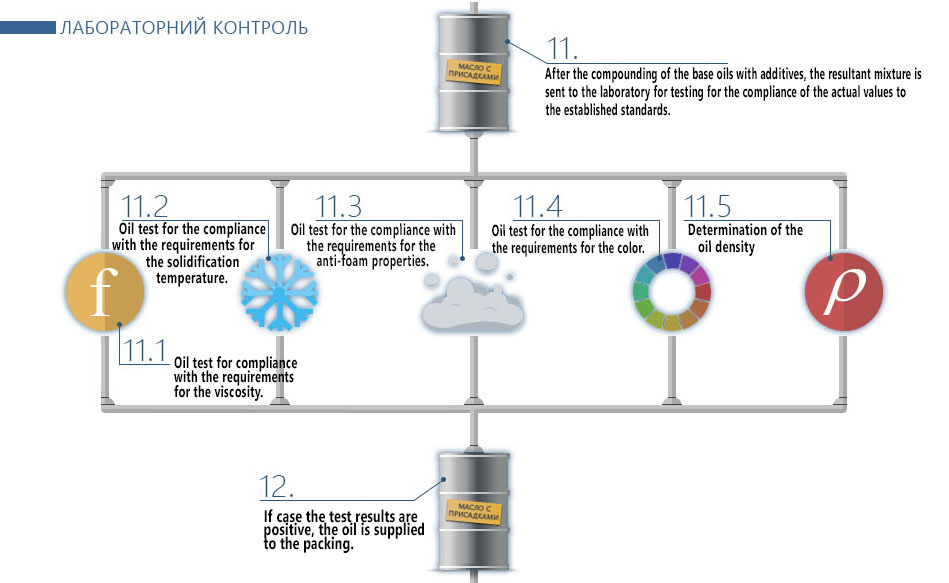

Oil test for compliance with the

requirements for the viscosity.

Oil test for the compliance with the

requirements for the solidification

temperature.

Oil test for the compliance with

the requirements for the

anti-foam properties.

Oil test for the compliance with

the requirements for the color.

Determination of the oil density

TESTING

ON THE NEWEST

EQUIPMENT

GLOBAL QUALITY

STANDARDS

PRODUCTS «GNL»

CONTACTS

Who seeks shall find

Tel.:

Fax:

E-mail:

Opening hours:

(044) 492-30-80

(044) 492-30-81

info@qil.com.ua

8:30-17:00